The U.S. Department of Energy (DOE) has officially unveiled the first group of winners for its groundbreaking Historically Black Colleges

Advanced Manufacturing

Post-High School CNC Training

Penn State DuBois and Continuing and Community Education are teaming up with Workforce Solutions for North Central PA and some

Multimedia

Construction

Transforming HVACR Education

Rapid advancements in Heating, Ventilation, Air Conditioning, and Refrigeration (HVACR) technologies have sparked significant enhancements in comfort, energy efficiency, sustainability,

Energy

Indianapolis Vocational Education Campus

Facilities managers face a growing skilled labor shortage amid a sharp decline in applications for skilled-labor jobs, according to data online recruiting

Transportation

Ford Auto Tech Scholarship

Ford Motor Co. announced that its philanthropic Ford Fund, along with Ford dealers, is investing $2 million in scholarship money

Technical Education Brief

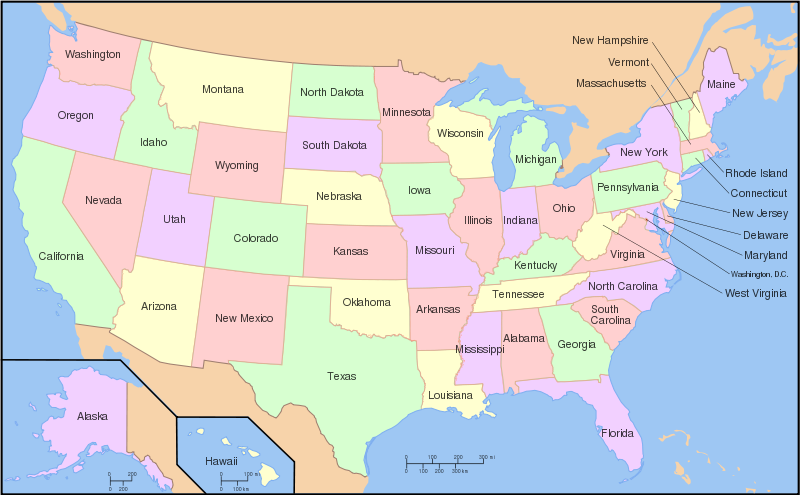

News by State

STEM

JUMPing Into STEM

Across the country, the clean energy transition is underway – with the private sector driving investments in energy-efficient technologies, manufacturing, clean

Encourage Diversity in STEM

As women and people of color continue to be underrepresented in STEM fields, Jayshree Seth, chief science advocate at 3M,

STEM Education in Nevada

Clark County School District (CCSD) STEM programs and educators continue to lead the state in quality STEM curriculum. Eight CCSD

Community Education In Esports

Esports is experiencing rapid growth in popularity, with projections of being worth over 2 billion in the next few years.

STEM Education for Chip Sector

The interdisciplinary nature of the semiconductor industry requires not just one education pipeline but many: Graduates with advanced degrees across

STEM Research Grant

Society for Science has recognized 41 exceptional educators with awards through its STEM Research Grant program, an initiative dedicated to