Spartanburg College Caters to a Changing Workforce

Even as the Industry 4.0 revolution charges ahead, creating new jobs and paving the way for unbounded automated manufacturing, employers struggle to fill their current openings. The skills gap has been plaguing American manufacturing for years now, but luckily the workforce is starting to notice.

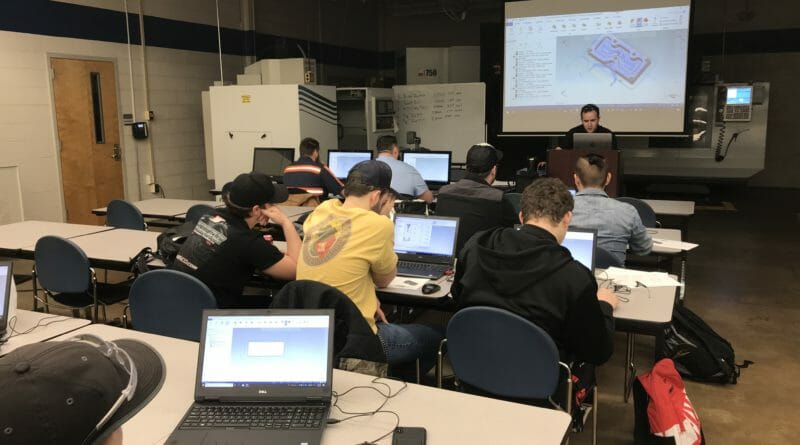

If you peek into a Machine Tool Technology and CNC class at Spartanburg Community College (Spartanburg, SC), you won’t find a large group of 20-somethings quietly listening to a lecture. Instead, you’ll find students from every stage of life working hard to solve real-world problems. According to Program Director Garrett Brown, these students are focused on forging a career in manufacturing – as machinists, CNC programmers, welders, and other trades. Their journeys to get to this classroom are all different, but the goal is the same.

Dallas Moss-Turner, a student in the Machine Tool program, heard about Spartanburg from his brother, a gainfully employed machinist at Sealed Air (Duncan, SC). Aaron Kitchens entered the workforce without a degree and decided to return to school after seeing how quickly machinists and programmers progress in their field. Ray Burgess shared,

“I never intended to be a machinist. I worked in shipping at Siemens, but I decided to move over when they started the tool and die apprenticeship. Siemens couldn’t find enough qualified candidates to be machinists. So, I came to Spartanburg.”

The Spartanburg classrooms are just as unique as its students. The school’s Center for Advanced Manufacturing & Industrial Technologies (CAMIT) is home to an array of manufacturing machines, including 16 lathes, 16 mills, five surface grinders, a few pedestal grinders for sharpening and tooling drill bits, a belt sander, a vertical band saw, and a horizontal band saw. The CNC shop alone has three standard 3-axis mills, three dual axis mills, a lathe with dual spindle and live tooling, a Haas 3-axis mill with a 5-axis trunnion, and a Haas UMC-750 5-axis mill. Twenty-five seats of Mastercam CAD/CAM Software (CNC Software, Inc., Tolland, CT) complete the shop.

When it comes down to which software fit Spartanburg best, Brown says the choice was obvious. “It’s fairly user-friendly as compared to other software that I’ve used, and it’s very powerful especially when you start getting into the multiaxis toolpaths.” Introducing students to an interface that is both simple enough to figure out and powerful enough to grow with students’ abilities is crucial. “It’s something that’s very familiar to students, because it looks like the Microsoft suite. There’s a ribbon at the top with Wireframe, Solids, and Toolpaths. You can just click on each individual tab and find all the buttons related to that subject.” The software is so intuitive that fellow instructor Shane Wood was able to teach himself how to use it.

That isn’t to say that Wood and Brown are completely on their own to figure the software out, though. Mastercam educational Reseller, Learning Labs (Calhoun, GA), provided training when they installed Spartanburg’s 25 seats, and industrial Reseller Barefoot CNC (Morganton, NC), provides continued support. “Barefoot CNC serves on our advisory board, a committee that meets twice a year. They come to give input on what’s going on in the CNC world,” said Brown. “They also offer training sessions if we need help in a particular subject. And, they’re always there to help us with any kind of troubleshooting.”

With a solid support system behind them, Brown and Wood are free to focus all their energy on teaching. “We try to choose projects that we have decided have practical applications in a factory,” said Brown. “That’s why we use CamInstructor.” The CamInstructor training program has offered online courses, textbooks, video tutorials, and training since 2007 for CNC programming, Mastercam, and SOLIDWORKSÒ. The curriculum, which has been tailored to fit any school or organization and any student’s skill level, provides a series of projects that teach new techniques as students’ progress while reinforcing previously learned skills.

Each student in the Machine Tool program receives their own instruction book to follow along with Brown. Students can watch Brown’s screen on an overhead projector and enter the same parameters that he does. “We go through every toolpath and then run Verify. It’s very helpful to the class if I make a mistake, as bad as that sounds, because then the students can see how it shows up on the simulation. We can use it as an opportunity to explain how to fix it and then run Verify again to show that it’s been fixed.” The Verify function highlights possible collisions in a graphic simulation so that programmers can easily check their toolpaths. Moss-Turner shared that Verify is his favorite feature within the software: “I love running the simulation and seeing the program come to life. I know that if I see that crash, I can go back to that feature and fix the issue.”

Once Brown has walked his students through a project, he gives them the entire next class period to try it on their own. “If we recognize that a lot of people are having issues with the same type of toolpath or if they have questions in general, we’ll pull it up on a projector and go over that as a class. We believe there’s no better way to learn how to use it than drive it and make mistakes. And that’s what I tell my students: ‘If you don’t know something, try it.’” Brown takes pride in knowing that his graduates will have a solid informational foundation on which to stand, and that they will also have the ability to improvise as problems arise. “We’ll usually walk through the way the book wants us to do it and then I show them how I would go about programming it on the job,” he continued. “Then they’ll do it on their own, and they can use either the method that they just learned, or they can come up with their own method.” As long as his students can create a high-quality part with efficient toolpaths, low cycle times, and good surface finishes, Brown is happy.

At the end of the two-year program, graduates leave not only with an associate degree, but also with certification from the National Institute for Metalworking Skills (NIMS), the organization that sets the industry skills standards for manufacturing trades. Spartanburg is set apart from most other South Carolina colleges in that NIMS certification is a requirement for graduation. Brown and Wood can confidently send their students out to find careers, knowing that they are prepared. Wood said, “It’s that extra step that makes Spartanburg stand out in the field. Our students will be prepared; that’s a promise.”

That promise seems to hold true. The Machine Tool Technology program at Spartanburg has about a 95 percent placement rate for all students who graduate. Locally, SEW Eurodrive, Holroyd Precision Rotors, Sealed Air Corporation, Gestamp, Siemens, and smaller local job shops are ready to hire Spartanburg graduates “For the past few years, we’ve had more job opportunities for our students than we’ve had students,” said Brown. The skills gap continues to pose problems for American manufacturing, but Brown has hope. “I think the tool industry in general needs to stop being such a secret. Kids never learn from their guidance counselors about going to a technical college for a trade, but you can make a very honest living in a trade.”