HS Math Meets Machining

Knox County Career Center (KCCC) is a vocational school that serves 663 students in grades 9 through 12. Situated 40 miles northeast of Columbus in the town of Mount Vernon, the school is surrounded by manufacturing powerhouses that include Ariel Corporation. HS Math Meets Machining .

Joe LaFevre teaches juniors and seniors in KCCC’s Precision Machining program. A 2007 graduate of the school, he spent 14 years working in industry before returning to his alma mater in 2021 as a precision machining instructor. LaFevre comes from a family of machinists; his brother and his uncle graduated from Knox County Career Center and his father owned a hydraulic business.

“I am proud of the fact that I get to come back to the school that I graduated from and help get kids off to the right start. But more importantly, I’m impacting manufacturing and my trade, machining, which I have such pride and passion for,” he said.

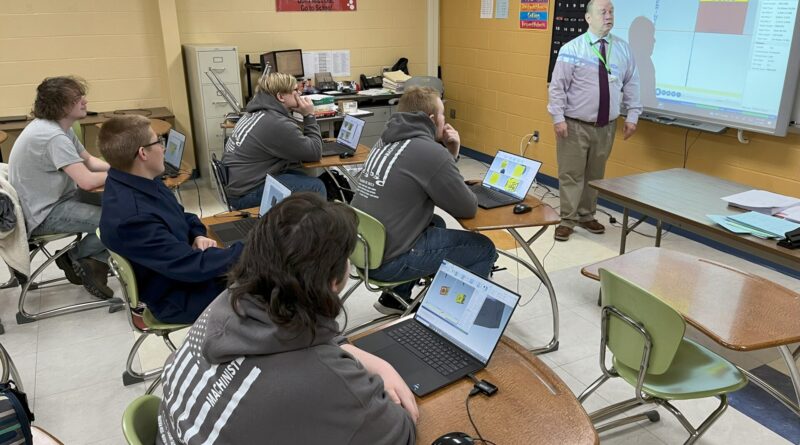

As a new teacher, LaFevre brings that pride and passion to the classroom. He stays current with CNC machining and software to ensure that his curriculum keeps pace with technology. He works in tandem with Lyle Reusser, a former business owner who, for the past 19 years, has taught math courses at KCCC.

Partnership Between High School Math and CNC Machining

“I am not a machinist. I have just worked very closely with our machining lab teachers,” he said. “Ten years ago, I approached our lab teacher at the time and asked what I could do to help support his class. He asked if I could learn CAD/CAM software, specifically, Mastercam® (Tolland, CT). He said that if I was willing to learn it, we’d make it work.”

Reusser agreed to the idea and, one decade later, the collaboration is still going strong. Reusser’s technical math class focuses on Mastercam while LaFevre’s students use the software to create blueprints and orthographic drawings.

Twelve seats of Mastercam 2023 run Haas VF-2 SS mills and Haas ST-10s lathes in KCCC’s machining lab. Here, Precision Machining program students create 3D parts and post process CNC programs. Students enrolled in the technical math class use the CNC lab during morning hours to produce parts that they designed in math class.

“Students use our precision machining lab to run their parts,” said LaFevre. “We are trying to get them to see parts from start to finish. We began using Mastercam for blueprints. Our seniors worked on a project at the beginning of the year. I thought it would be a good gauge to give them a product and have them reverse engineer it.”

Outcomes

Their task was to produce blueprints and manufacture six vices within four weeks. The students divided into their groups and formed departments, including engineering, quality, and assembly. One student responsible for engineering drafting hand-sketched designs then transferred his design ideas into Mastercam. The software’s latest release offers its most intuitive interface yet, a feature that users, especially new ones, appreciate.

The students design parts in three dimensions and then post-process a CNC program. According to both teachers, the students enjoy using the CAD/CAM software. Once they have successful, finished products based on their own designs, their excitement is evident. One recent project really grabbed their attention. Last year, the technical math students created a 2-inch by 2-inch by 2-inch aluminum cube within a cube known as a knockout block. They designed each face to include engravings of desired elements such as favorite sports teams, geometric shapes, names, and jersey numbers.

“It turned out to be a terrific project for them because they were drawing it, designing it in Mastercam, then running it. They showed excitement for the project and took pride in completing it,” said LaFevre.

Project Progression

Through the knockout block project, Reusser teaches several CAD properties. Students learn about planes and how to manipulate them. Parameters are provided so they can design their own parts.

“It’s actually a pretty big hit and draws a lot of interest,” he said. “We get the part designs ready in my math classroom, and then we take the code to the Haas controller down in the manufacturing lab where Joe (LaFevre) oversees machining.”

Most of the students can find their machine zeroes and perform part set up. LaFevre then guides them through machining strategies and ensures that safety procedures are followed. Though KCCC does not yet have 5-axis machines, by the end of the two-year program, its novice machinists become well versed in 3-axis machining.

Reusser and LaFevre predetermine class projects and usually start with something simple, such as drilling holes, basic milling, and contours. Reusser designs a part then teaches geometry as he covers the steps needed to create it. LaFevre then handles the actual machining, including setup, controllers, feeds, and speeds. The two teachers meet each week to discuss current projects and determine what is needed to finish them. Seniors often drop in during the juniors’ labs to get a glimpse of their younger schoolmates’ projects.

“There’s a bit of a wow factor with some of our projects,” said Reusser, who creates drawings then lets Mastercam generate the corresponding code. “I teach a math class, but I incorporate Mastercam because it is designed to be a hands-on, project-based class. We’re not using tight tolerances to machine air foils or other intricate parts, but we have the kids create things that they can personalize and take to interviews.”

Filling Portfolio

The idea is to provide a chance for young interviewees to talk about their projects and explain what was learned from a given project, from both the programming and machining standpoints. Overall student feedback regarding the software remains positive, though a few bumps may occur along the way.

“Any time students come to me to say that the software does not work, the problems have always been with their setups—every time,” said Reusser.

“I’m always impressed with Mastercam’s capabilities, and we’re just using just a tiny piece of its real capability,” said Reusser. “I hope that as time goes on, we’ll get students in more advanced classes doing more like 4- and 5-axis projects, which would be a lot of fun.”

Industry to Education

An advisory board that includes Ariel Corporation, consulting firm Salas O’Brien, and Strassel’s Machine Inc., plays a major role in the success of KCCC and its graduates. Customer support from Mastercam Reseller FASTech, Findlay, OH, adds another layer of expertise to the school’s math and machining equation. Customer visits, onsite training, email and phone support, and FASTech’s Teach the Teacher training seminars have proved invaluable to KCCC. For educators who teach Mastercam, CAD/CAM curriculum and support materials include project-based learning modules, courses, and textbooks plus several online tools including camInstructor.com and StreamingTeacher.com.

For the teachers and students of KCCC, the combination of math and machining classes has produced positive results. Graduates are equipped to find solid, well-paying jobs.

“Mastercam is really our tool,” said Reusser. “All of the projects that we’ve done were machined or designed with it. And if it wasn’t for Mastercam, we wouldn’t have been able to do one tenth- even one hundredth—of those.

“It is something that we use often. We know that local industry is going to lean hard toward Mastercam, so we want to make sure that our students are prepped and ready to meet those needs. If they can put that on the resume, or say they have a good understanding of CAD/CAM programming, that can probably get them in the door and get them a good start.”

SOURCE: HS Math Meets Machining

High School Math Meets Machining at Ohio Career Center

Knox County Career Center https://www.knoxcc.org/

https://www.techedmagazine.com/category/news-by-industry/manufacturing-education/

HS Math Meets Machining