CNC Education in America

Why tech schools are taking the LEAP into Siemens’ advanced CNC training

Rapid advancement in technological development has changed and challenged industries around the world in recent years. In manufacturing, as new technologies permeate the industry, the demand for employees with advanced machining skills increases. Those that possess the latest skills will quickly rise to the top of the talent pool.

Progressive high schools and community colleges around the country that sense an opportunity to meet the growing needs of the industry are turning to the Siemens Lifelong Educational Advantage Program (LEAP) to equip their students with career-enabling, advanced machining skills. The LEAP curriculum features basic-to-advanced computer numerical control (CNC) machining, including 5-axis training, that puts students on a path to a career, not just a job.

“The manufacturing industry is investing heavily in and quickly moving to 5-axis machining, so 5-axis capabilities are becoming necessary for shops,” says Steve Holmes, CNC Education Manager at Siemens. “Students must learn 5-axis machining to obtain the best, highest-paying jobs at the best companies.”

LEAP-certified schools use the Siemens SinuTrain training system, which is PC-based simulator software replicating the SINUMERIK Operate interface of 828D and 840D controls. Siemens provides software and installation assistance as well as free instructor training, certification, and support.

The LEAP training program consists of three days each on Level 1 (conversational programming, ShopTurn and ShopMill), Level 2 (more complex machining, including 4-axis), and Level 3 (5-axis milling) for instructors. Upon completion of training, instructors are certified, and they in turn can certify students. Successful completion of each level of training and subsequent testing can provide students with up to five certificates to help them begin their careers in CNC machining.

Markus Puntigam, technical sales manager at EMCO Group USA in Wixom, Mich., has firsthand experience with LEAP. EMCO supplies many of the machines using Siemens controls to schools in the LEAP program. He says LEAP benefits not only the students, but also the schools.

“The LEAP program has real market value,” Puntigam says. “The schools get—free of charge—three-levels of training, each level backed by three days of instructor training—that is a full nine days of training. Part of that training can be done at the school on site. Schools are getting a training service package in the range of $25,000 dollars for free.”

Many schools around the country already are part of the Siemens LEAP program, giving their students the game-changing capabilities employers seek. Program leaders at three of those schools in Fort Worth, Texas; Cupertino, Calif; and Oklahoma City say the program has elevated their curriculum—and they are ready for even more advanced machining training and certification.

“Schools must improve their programs to incorporate 5-axis because the market is going that way, otherwise, their programs won’t be in demand,” Holmes says.

Hollenstein Career and Technology Center—Fort Worth, Texas

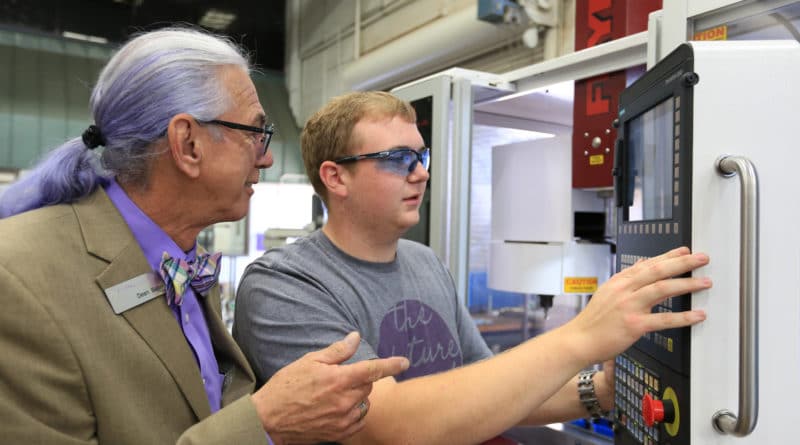

Demetrius “Coach” Anthony, a tool and die maker journeyman who served in the military, started the manufacturing/engineering program at Eagle Mountain-Saginaw ISD-Hollenstein Career & Technology Center in Fort Worth, Texas, eight years ago. He has seen increasing demand for employees with advanced CNC machining skills, and the Siemens LEAP program is helping Anthony train Hollenstein students with the latest technology. His classes feature several EMCO machines with a Siemens 840D emulator, which gives the students valuable experience that is attractive to high-tech companies.

“If any of our students ever wanted to go to an advanced manufacturing company using a Siemens controller, that’s the technology and skill set being used,” says Anthony, an instructor and former high school football coach. “I’m always looking at different things that I can teach the students to give them an extra tool in their bag.”

Holmes says that strategy will pay off for Hollenstein students.

“Graduates with experience in advanced technology are in great demand by the manufacturing industry,” he says. “These companies are asking for students that know the Siemens platform and that know 5-axis machining.”

In his classrooms, Anthony has seen students quickly improve using Siemens controls. He attributes that in part to the conversational programming feature.

“Once I brought Siemens in, those students who struggled with code got to see the conversational part of it, and they took off with it,” Anthony says. “When they can see it before they actually run their simulation, it helps them. It gives them that visual, because a lot of people are visual learners, like I was. You’ve got to show me. I want to see it, because if you just talk about it and tell me in theory, I don’t quite understand it. …“On our other control option, all they see is the line of code, and they’ll see a 2D line tracing the moves it made. That’s it. They don’t get the 3D visual like what they do with the machines with the Siemens controls we have now.”

Under his guidance and with hands-on experience with Siemens-controlled machines, students who complete the LEAP program at Hollenstein are ready to enter the workforce, Anthony says. He shows local employers his students’ skills during open houses, where company representatives often tell him a variation of a common theme: It’s hard to believe high school students can machine.

“I’ll have one student, and I’ll say, ‘Here’s a student; he can draw up any part that you have in CAD (computer-aided design). … He can set it up. He can do the CAM (computer-aided manufacturing) or he can hand-program it. He can run the machine, set the machine up. He can go over and help with the mech lab units, which is essentially lighting the POC (proof of concept)—controlling the conveyor, sensors, things like that—and then he can print up 3D models.’ This is all coming from one student,” Anthony says. “One of the guys who came out from a local large manufacturing company says, ‘We have four or five different people doing all those things.’ And I said, ‘Here you have a student who has the very basics for all of that, and he’s ready to go.’ ”Puntigam of EMCO, which supplies machines to Hollenstein, says it is exactly that type of employee that is highly sought in the industry: “not a button-pusher, but somebody who really knows what they’re doing.”

Anthony’s students also rise above their peers in the state and national SkillsUSA competitions that showcase the best career and technical education students in the country. He says his students, using Siemens controls, often win their district and finish in the top three, if not win, in the state SkillsUSA competitions.

“We prepare for competitions and for the workforce at the same time,” says Anthony, whose program is so popular, students must enter a lottery for enrollment.

De Anza College—Cupertino, Calif.

Situated in the heart of Silicon Valley in Cupertino, Calif., De Anza College’s Mike Appio is in a prime location to see and hear about the cutting-edge machining technologies and skills that are most in demand at some of the country’s top companies. Appio, coordinator of De Anza’s Design & Manufacturing and Technologies department, wants his program to reflect those industry needs and “stay one step ahead of the rest of the community colleges.” He’s turning to the Siemens LEAP program to do that.

Appio, who’s been with De Anza for more than 13 years, has a DMG DMU 50 machine with a SINUMERIK 840D controller in his program. Students start their training with 3-axis machining on Haas equipment, then work up to multi-axis machining, automation, and Siemens NX.

Many of the students that enter the design and manufacturing program at De Anza already have earned bachelor’s degrees, Appio says, but return to school because they need experience and training with advanced machining technology like the Siemens 840D.

“There are a lot of companies in the Silicon Valley that want to know ‘Do you have any machining experience?’ It’s not like you need 20 years under your belt, it’s: ‘Have you run equipment? Are you familiar with equipment?’ ” Appio says.

Appio wants De Anza students to be able to answer that question by pointing to their work learning Siemens’ Sinumerik 828D and 840D controls via the LEAP program training. He particularly covets training and certification on the 840D, a worldwide favorite because of its capabilities in high-end machining.

“We want to do certification on the 840D because there are larger companies around like Northrop Grumman and others that are using the 840D controller on not only DMG Mori Seiki but other machines,” he says. “That’s the direction we want to work toward, unlike other education approaches that use introductory level machines. You’ve got to expose students to various things.”

The SinuTrain software that teaches students those basic-to-advanced machining skills is very close to a real-world experience, Holmes says. It turns a PC screen into an exact representation of the SINUMERIK Operate interface; the numeric control kernel (NCK) that drives the software is the same NCK that drives Siemens 828D and 840D controls.

Among SinuTrain’s many features, collision-avoidance is especially beneficial for students, Holmes says.

“Collision-avoidance is not only going to find errors in the program, but it’s also going to prevent the machine from crashing, which can be very, very costly,” he says. “In a learning environment, having a tool like SinuTrain with collision-avoidance is incredibly beneficial.”

For Appio, the LEAP program certification is important for his students and De Anza in general. He says it will set both apart from the pack.

“A certification on a Siemens 840D, 828D, that’s going to put you in a whole different ballpark, a whole different arena,” he says. “These people thirst for something else to put on their résumé, another skill. In the whole Bay Area here, across several million people and 10 community colleges, no one is issuing these certificates. No one’s doing it all. So I’m giving them another avenue to get students jobs.”

Holmes says that is a route that will lead to success.

“The students that successfully complete LEAP, especially the 5-axis program, will be in the biggest demand and command the highest salaries in the industry,” Holmes says.

Francis Tuttle Technology Center, Portland Campus—Oklahoma City

“Please write.”

That’s all Dean Baker was told to do when he began writing G-code for machining controls in 1979. His instructor, a Japanese engineer with little command of the English language, would show Baker a blueprint and give that simple, two-word command. Baker would do his best to write the code, then the instructor would correct his work.

“That’s when it dawned on me—it’s what I tell my students now—that this is a different language,” Baker says. “Back then, G-code was a language by which we both could communicate, at least as far as manipulating a machine to do something for us.”

Now, Baker is the one doing the teaching. He is instructor of Manufacturing Technology Machining at the Francis Tuttle Technology Center’s Portland Campus in Oklahoma City. He’s using more than blueprints and “please write” to teach advanced machining, however. Baker’s students work with, among others, a Fryer machine powered by the Siemens SINUMERIK 828D control. Baker sees LEAP and the 828D training as the next step for his program.

“It’s just an awesome, awesome control,” he says. “I’ve barely scratched the surface with it—I’m real excited to get in there and get my hands on it and make some stuff.”

Baker, a self-proclaimed “G-code guy,” calls the conversational feature of the 828D “pretty cool.”

“I still teach G-code programming,” says Baker, who is also secretary of the SkillsUSA board of directors. “But with conversational, that enables students to see. Instead of just, ‘OK, I’m pushing this, and this is going to happen,’ conversational teaches what’s happening behind the scenes. I know what the machine’s doing.”

Similar to Anthony’s students at Hollenstein Career and Technology Center in Texas, Baker says the 828D’s conversational programming resonates in his classes.

“I’ve had students understand [G-code], but they’re just not as good with it,” he says. “Then they’ll get on a conversational control and—bam—it seems to fit their personality or their skill set, and they do great on it.”

His classroom experience with the 828D control has pushed Baker to advocate for conversational programming supported by the Siemens SINUMERIK CNC platform in future SkillsUSA competitions.

“SkillsUSA is a very progressive organization. We always want our students to learn and our instructors and teachers to deliver the latest technology. To me, the 828D represents the latest in CNC machining technology,” Baker says. “Haas does a good job putting on the CNC G-code contest right now, but as an instructor, I think we should also have a CNC conversational contest. Two different controls.”

Being an instructor along with being a SkillsUSA board member gives Baker a unique and educated perspective on the organization’s mission. He sees conversational as a trend that will help shape a new generation of CNC professionals, and he doesn’t want any students left behind.

“You always have to be forward-looking,” he says. “Our SkillsUSA competitions drive behavior immediately, adapting new technologies out there, getting them more and more common.

“At competitions, students introduce these new technologies at the national level. From a board directive, we want to make sure that the greatest number of students possible are able to participate.”

To learn more, or to join the Siemens CNC LEAP program, visit usa.siemens.com/cnc-leap or email cnc-leap@siemens.com for information.