Future of PLC Programming

Sarah McGhee is product owner, Simatic AX, at Siemens. Future of PLC Programming.

What is the primary focus of software-defined automation (SDA)?

Sarah McGhee, product owner, Simatic AX, Siemens: The primary focus of software-defined automation (SDA) is to leverage proven methodologies from the software development space and apply them to the OT space. This focus can be broken down into several key pillars:

- Integration of IT-oriented tools: Utilizing IT-oriented tools brings software engineering practices into the automation programming space. While automation does not always allow for the “fail fast and break things” approach typical in software development, it should enable rapid iteration in a safe manner.

- Virtualized programmable logic controllers (PLCs) and controls: With the creation of virtualized PLCs, we are concretely decoupling control tasks from hardware devices and providing the ability to run them on high-performance industrial PCs or computers, increasing flexibility and scalability. This approach also facilitates easier integration with other applications.

- Data-driven production: Leveraging data collected from automation systems to make intelligent decisions or suggestions is critical. With the addition of artificial intelligence (AI) models, it is essential to utilize data effectively to enhance automation systems. For example, predictive-maintenance algorithms can analyze data to foresee equipment failures and optimize maintenance schedules.

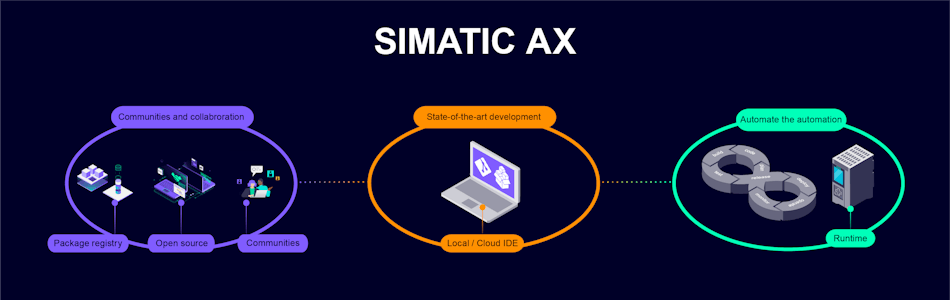

In summary, SDA focuses on integrating IT tools, virtualizing control systems and utilizing data-driven approaches to create more flexible, scalable and intelligent automation solutions (Figure 1).

Next steps

- Explore how to implement virtualized PLCs and data-driven production strategies within machinery designs to increase flexibility and efficiency.

- Assess current skillsets and identify areas where proficiency in IT-oriented tools and software development methodologies need to be developed.

- Discuss adopting modular automation system designs to improve update processes and respond faster to customer demands.

- Research Siemens Simatic AX to understand its capabilities and how it can integrate with current PLC programming workflows.

Source: Future of PLC Programming

The future of PLC programming: How software-defined automation is transforming industrial control

Why this article is important

- It details the shift toward virtualized PLCs. This directly impacts how controls engineers will design and implement future machinery control systems.

- It emphasizes the integration of IT tools and data-driven production. Requiring controls engineers to expand their skill set beyond traditional PLC programming. Including data analysis and software development methodologies.

- It highlights the importance of modular design and adaptability in automation systems. Enabling controls engineers to build more flexible and easily upgradable machinery.

- It explains how SDA’s sustainability benefits can influence customer demand and company priorities, requiring controls engineers to consider resource efficiency and environmental impact in their designs.

https://www.techedmagazine.com/category/news-by-industry/manufacturing-education/