Robotics Supports Student Success

Seven robots are in residence in the sub-basement of the Yale School of Architecture’s Rudolph Hall. Made of industrial-grade aluminum, these one-armed, six-axis wunderkinds sit motionless at workstations. They come alive during the popular class “Introduction to Architectural Robotics,” when graduate students fit them with 3-D printed tools and program them for precise automated action. Robotics Supports Student Success.

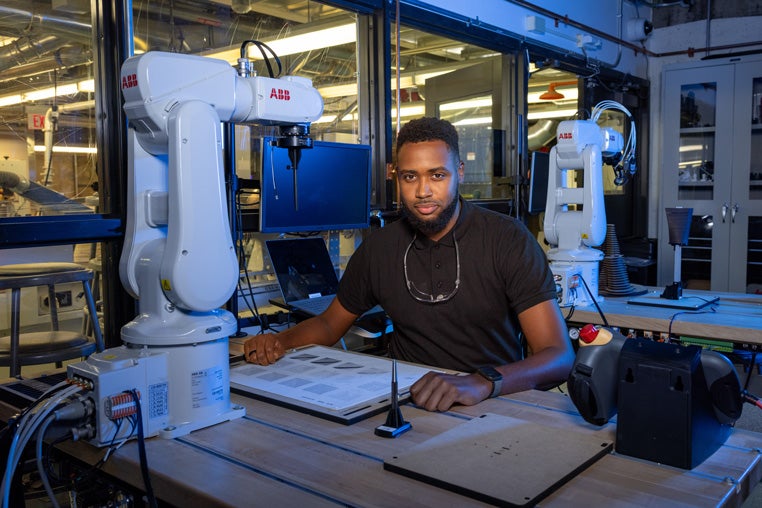

Each semester, the 12 students who get into the course are required to learn how to use robots as a tool, a skill that has been forecasted to become more and more integrated on construction sites. Robotics expert and lecturer Hakim Hasan created the curriculum and teaches the course. A native of Belize who has long been captivated by technology, Hasan is an international leader in the field of integrating robotics with architecture.

The students conduct their work in a robotics lab that was conceived of and created by Vincent Guerrero, director of advanced technology, and his team of professionals, all staff members who support the school’s faculty and students. He worked with senior systems programmer Robert Liston, dev-ops software engineer Nils Carlson, advanced technology and fabrication specialists Trevor Williams and David Liston, and advanced technology specialists Jorge Quintana, Marquis Lockhart, and John Minardi. Guerrero and his team also have a close partnership and collaboration with the Fabrication Shop, its manager Nathan Burnell, and assistant Alyse Guild.

First came the lab.

Guerrero and Hasan have been collaborating closely ever since Guerrero transformed an underutilized space into a hotbed of activity. “Space is very tight here at Architecture, so whenever we get a chance to transform and repurpose a room, we grab it,” said Guerrero. “It is a great opportunity that does not come along often.”

Guerrero started pre-planning for a new lab in 2018, the year he took over as director of advanced technology, having spent most of his career in IT at the School of Architecture. At that time, the space was filled with a six-foot tall Kuka robot that was cutting edge when it was purchased and installed in 2006. But in the years leading up to 2018, it had fallen out of favor with professors and students. It was a subtractive cutting device to which students could add a blade to cut foam and wood, a complex task.

“If you were a student using the robot as part of the curriculum, you would have to dedicate a week to learn the setup before getting your work done,” Guerrero said. “It was getting less and less use, and only two to three students could work in the space at a time.”

Interaction with Robotics Supports Student Success

Guerrero’s goal was to make the space into a classroom where multiple students could interact with robots. He and his team brainstormed and strategized with help from Dean Deborah Berke, Associate Dean Phil Bernstein, and Timothy Newton, the director of the fabrication shop. When the project was approved, Guerrero searched for the best robot in terms of size, capability, and industrial acceptance across the industry. The ABB IRB120 model made a lot of sense, and he purchased seven for the classroom.

“We spec’d the custom tables and designed a rail so the robots could slide back and forth, depending on what was being done in the classroom,” said Guerrero.

Acting as project manager, he worked with his team to place the robot controllers underneath the desks. They also installed the classroom technology, including the usual equipment for a hybrid digital room—microphone, camera, back and front speakers, giant screen, and monitors that swiveled—and added keyboard trays for laptops.

Then came the curriculum.

Hasan joined Yale to create the curriculum and teach the robotics course largely because the technical infrastructure was in place. “From the outset, our shared vision has kept us in perfect alignment, and it’s truly reassuring to have their support,” said Hasan.

Drawings created by School of Architecture student Tony Wang using a custom 3D-printed pen tool attached to the ABB IRB120 Robot as part of a project for “Introduction to Architectural Robotics.”

Hasan and Guerrero have done some fine-tuning over the last three semesters, adding a toolbox to each workstation so the students have everything they need to 3-D print tools for the robots. The external monitors are now clamped to the end of the tables and anchored to the walls to reduce the shaking that occurred when the robots were in motion. While Hasan’s curriculum evolves every semester, at its core is the belief that the future of building construction involves robots. “We aspire to be at the forefront of innovation, preparing our students to excel in the realm of automated building design,” said Hasan. “Within this relatively novel field, I craft the curriculum with a keen focus on addressing the deficiencies I’ve identified in conventional robotics education, tailoring it specifically for architectural designers.”

A shared vision and a shared success

Introduction to Architectural Robotics has become one of the most sought-after electives at the School of Architecture. Because of this, when it came time to transform another space and add new capabilities for the community, it made sense to build something that could also complement the robotics lab. “That new space is what we’re calling the Additive Lab, with technologies like precision reinforced 3D printing, small-format precision 3D printing, and robotics-based six-axis 3D printing,” said Guerrero. “We want to make sure we stay far ahead of the newest technologies and trends so our students leave here with cutting-edge experience so they can be leaders in the profession.”

Source: Robotics Supports Student Success

https://your.yale.edu/youryale

https://www.techedmagazine.com/category/news-by-industry/manufacturing-education/